Sensitec GmbH

Schanzenfeldstr. 2

35578 Wetzlar

Qualitätsmanagement

Qualität ist ein Maßstab für uns

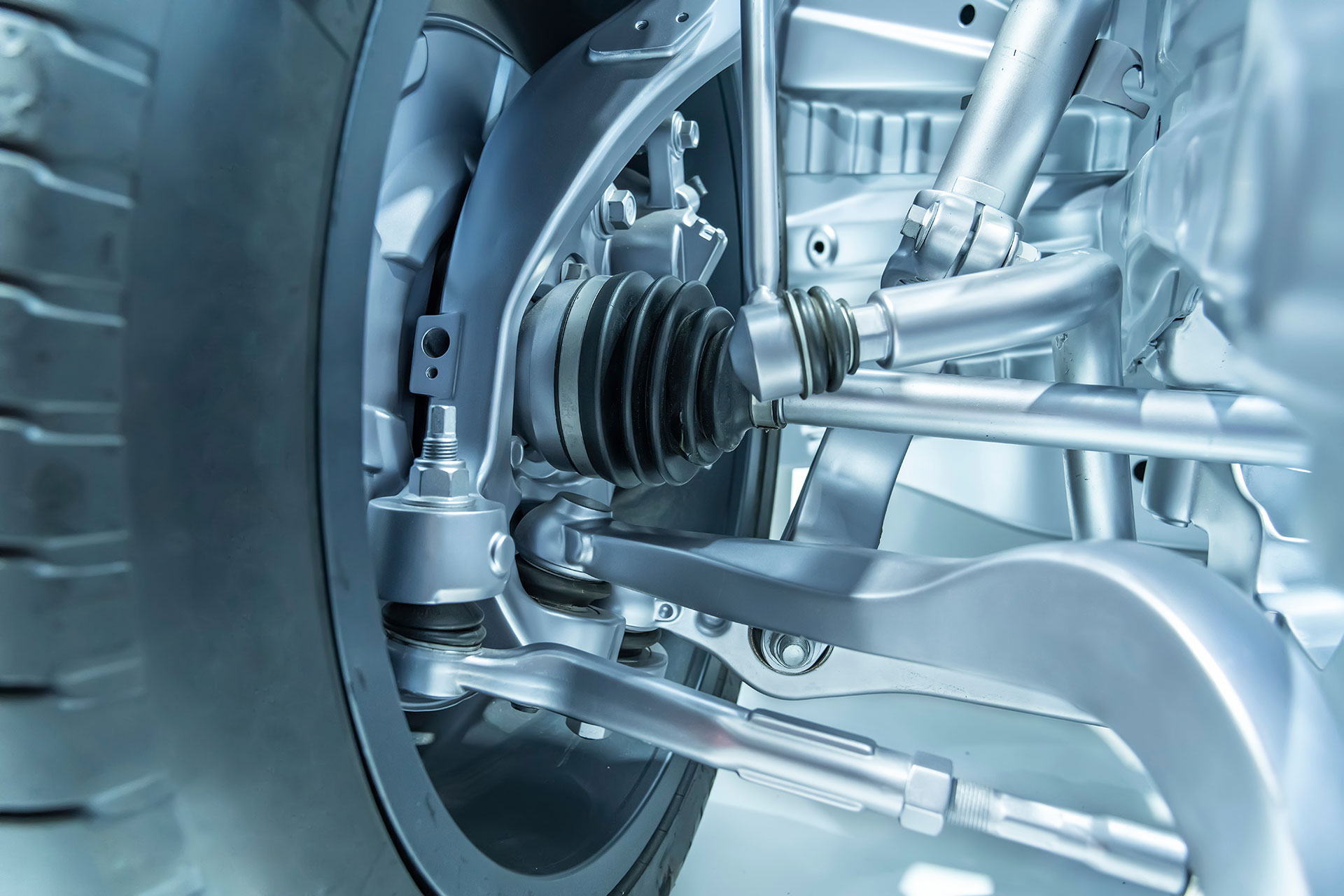

Produktqualität kann man prüfen. Doch damit allein geben wir uns bei Sensitec noch nicht zufrieden. Der Qualitätsanspruch von Sensitec bezieht sich auf alle Prozesse im Unternehmen, angefangen bei der Produktentwicklung, die wir mit unserem Kunden gemeinsam definieren, über termingerechte Lieferung bis hin zu einem kompetenten Kundendienst. Alle Aspekte unserer Kunden-Lieferanten-Beziehung unterliegen dem einheitlichen Ziel die Bedürfnisse unserer Kunden zu erfüllen. Mit Einführung eines QM-Systems und der Festlegung unserer Geschäftsprozesse haben wir erreicht, dass alle Prozesse in unserem Unternehmen kontinuierlich überprüft und damit einer ständigen Verbesserung zugeführt werden. Um die insbesondere in der Automobilindustrie extrem strengen technischen Spezifikationen hinsichtlich Produktqualität und Produktivität zu gewährleisten, erhielt Sensitec die Zertifizierung gemäß IATF 16949:2016, die den Qualitätsmanagementstandard für Lieferanten der Automobilindustrie festschreibt.

Unsere Zertifikate